Focus Companies

Aertesi Srl

• 01.10.2014

This article is over 3 years old

Aertesi combines the advantages of a fan coil unit with chilled beams into a single product: innovation, comfort and performance

The advantages of an induction plant (chilled beam) together with a fan coil performance: innovation in new FCB by Aertesi.

FCB, standing for Fan Coil Beam, combines the benefits of an induction plant (chilled beam) with the performance of a traditional fan coil.

In its simplest description, fan coil beam by Aertesi is an advanced solution for cooling and heating systems.

Let’s try to understand the distinctive characteristics of this hydronic terminal, allowing easy installation above a drop ceiling.

In terms of Indoor Air Quality, a chilled beam system usually requires a higher air flow than a FCB system.

This is due to the need of creating an induction sufficient to let the plant itself operate; furthermore, the temperature of water circulating through the heat exchanger of the chilled beam is significantly higher in order to avoid the risk of condensation. The chilled beam is installed in full view to ensure a good level of air exchange in crowded environments and it may also require additional vents which may impact and bind the furnishing choice.

On the other side, choosing a FCB system allows the user to choose the cooling capacity, the air flow and the noise level, according to real needs. The EC motors allow continuous adjustments of the fan speed at three different modes: Silent - Standard - Booster, which are all suitable for residential, commercial and hospital applications.

In the case of chilled beams, the air flow required to ensure the cooling capacity is significantly higher than the one required by a FCB system and has a pre-treatment battery of larger size for the dehumidification of air, given that it is not able to condensate directly within the system terminals.

For the dehumidification of air, a FCB system just requires a smaller battery, since it is equipped with a condensate drain pan kit with optional discharge pump. In addition, FCB complies with Eurovent standards.

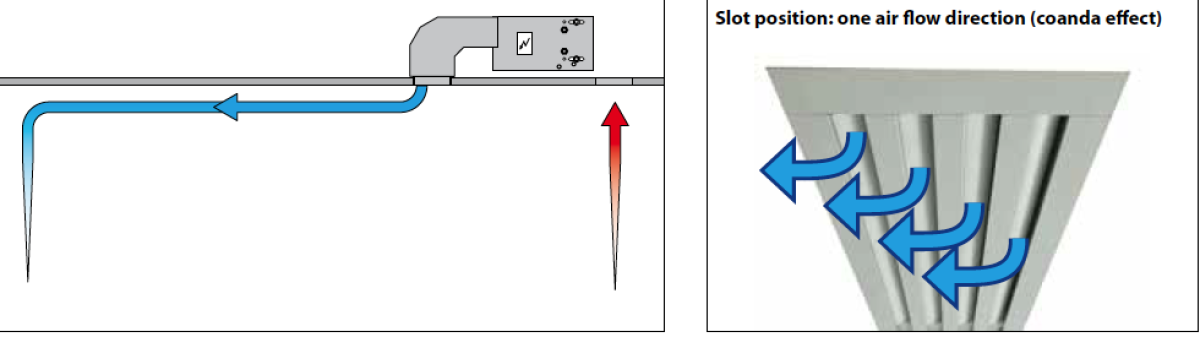

The choice of EC motors makes the Fan Coil Beam extremely quiet and reduces turbulence and noise detectable in traditional hydronic systems. The only visible part is the grille with adjustable fins which allow proper internal temperature management; the Coanda effect and the absence of cold rain create a comfortable environment.

These technical aspects act in favor of a FCB plant in terms of adaptability, application flexibility and air well-being. Thanks to its versatility, the designer engineer can size the system so that FCB may also work as a simple chilled beam.

Fan Coil Beam advantages:

• Works with water temperature through the circuit at three steps (7/12°C-10/15°C-15/18°C);

• High energy efficiency and low power consumption of the plants;

• High comfort and better performance compared to traditional fan coils;

• EC motor quiet operation;

• High cooling/heating power;

• Adjustable diffusers with Coanda effect;

• Works with a chilled water system;

• Equipped with a condensate drain pan kit;

• Internal exchanger with 2 or 4 pipes;

• Installation above a drop ceiling and aesthetically non-invasive.

In its simplest description, fan coil beam by Aertesi is an advanced solution for cooling and heating systems.

Let’s try to understand the distinctive characteristics of this hydronic terminal, allowing easy installation above a drop ceiling.

In terms of Indoor Air Quality, a chilled beam system usually requires a higher air flow than a FCB system.

This is due to the need of creating an induction sufficient to let the plant itself operate; furthermore, the temperature of water circulating through the heat exchanger of the chilled beam is significantly higher in order to avoid the risk of condensation. The chilled beam is installed in full view to ensure a good level of air exchange in crowded environments and it may also require additional vents which may impact and bind the furnishing choice.

On the other side, choosing a FCB system allows the user to choose the cooling capacity, the air flow and the noise level, according to real needs. The EC motors allow continuous adjustments of the fan speed at three different modes: Silent - Standard - Booster, which are all suitable for residential, commercial and hospital applications.

In the case of chilled beams, the air flow required to ensure the cooling capacity is significantly higher than the one required by a FCB system and has a pre-treatment battery of larger size for the dehumidification of air, given that it is not able to condensate directly within the system terminals.

For the dehumidification of air, a FCB system just requires a smaller battery, since it is equipped with a condensate drain pan kit with optional discharge pump. In addition, FCB complies with Eurovent standards.

The choice of EC motors makes the Fan Coil Beam extremely quiet and reduces turbulence and noise detectable in traditional hydronic systems. The only visible part is the grille with adjustable fins which allow proper internal temperature management; the Coanda effect and the absence of cold rain create a comfortable environment.

These technical aspects act in favor of a FCB plant in terms of adaptability, application flexibility and air well-being. Thanks to its versatility, the designer engineer can size the system so that FCB may also work as a simple chilled beam.

Fan Coil Beam advantages:

• Works with water temperature through the circuit at three steps (7/12°C-10/15°C-15/18°C);

• High energy efficiency and low power consumption of the plants;

• High comfort and better performance compared to traditional fan coils;

• EC motor quiet operation;

• High cooling/heating power;

• Adjustable diffusers with Coanda effect;

• Works with a chilled water system;

• Equipped with a condensate drain pan kit;

• Internal exchanger with 2 or 4 pipes;

• Installation above a drop ceiling and aesthetically non-invasive.