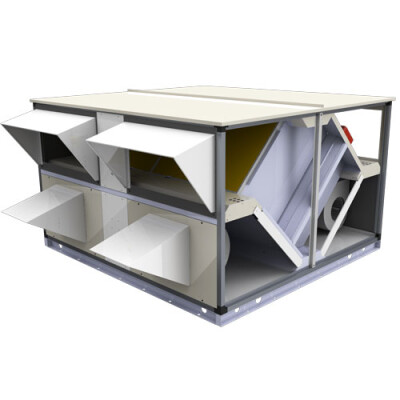

Thermodynamic heat recovery units series CFR-HP

The characteristics of these units make the plant installations easier, especially when they are really difficult (and much more expensive) by using common heating/cooling systems.

Description

The CFR-HP heat recovery units by SIC Srl are distinguished by twin heat recovery system for transferring the energy otherwise lost when extracting air from the room: the first system, static type, by aluminium plated crossflow heat recovery, the second system (in sequence to the previous one) by electric driven air-to-air R410A heat pump device.

Therefore, by a single independent system and at the same time, it can match the needing of ventilation while ensuring room comfort, the outside air thermal loads and the energy saving, due to the very high unit efficiency, both on winter and summer time.

Together with their compact dimensions, the characteristics of these units make the plant installations easier, especially when they are really difficult (and much more expensive) by using common heating/cooling systems. These units can be perfectly integrated into traditional room heating/cooling systems, placed in sequence or in parallel.

CFR-HP series is composed of five sizes, horizontal version only, to cover a needing of ventilation from 600 up to 3200 m3/h. The models of the series CFR-HP can be given with a ionization system of the air called BIOXIGEN®. This system, unique in his type, makes the air and surfaces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

Therefore, by a single independent system and at the same time, it can match the needing of ventilation while ensuring room comfort, the outside air thermal loads and the energy saving, due to the very high unit efficiency, both on winter and summer time.

Together with their compact dimensions, the characteristics of these units make the plant installations easier, especially when they are really difficult (and much more expensive) by using common heating/cooling systems. These units can be perfectly integrated into traditional room heating/cooling systems, placed in sequence or in parallel.

CFR-HP series is composed of five sizes, horizontal version only, to cover a needing of ventilation from 600 up to 3200 m3/h. The models of the series CFR-HP can be given with a ionization system of the air called BIOXIGEN®. This system, unique in his type, makes the air and surfaces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

Technical features

- Frame made from extruded Anticorodal 63 aluminium alloy bars, connected by 3-way reinforced nylon joints;

- Sandwich panels, 23 mm thickness, galvanized sheet metal inner skin and precoated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation;

- Filtering sections at both air intakes complete with G4 efficiency cell filters, extractable from both lower and side removable panels;

- Direct driven double inlet forward curved centrifugal fans;

- First step of energy recovery (static type) by air-to-air crossflow aluminium heat exchanger; lower drain tray, estende to the whole area of heat treatment;

- Second step of energy recovery (dynamic type) by air-to-air R410A heat pump system composed of electric driven compressor (rotating or scroll type depending on unit size), evaporating and condensating reversible Cu/Al finned coils, electronic expansion valve, liquid receiver and separator, 4-way reversible valve, high and low pressure switches, biflow freon filter, liquid indicator;

- Built-in electric box to control power loads, NTC temperature sensors on both air circuits, electronic controller to control room temperature, heating/cooling mode and defrost cycles; remote control panel (up to 30 m far from the unit), already prearranged with Modbus RTU protocol for Building Management System.

- Sandwich panels, 23 mm thickness, galvanized sheet metal inner skin and precoated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation;

- Filtering sections at both air intakes complete with G4 efficiency cell filters, extractable from both lower and side removable panels;

- Direct driven double inlet forward curved centrifugal fans;

- First step of energy recovery (static type) by air-to-air crossflow aluminium heat exchanger; lower drain tray, estende to the whole area of heat treatment;

- Second step of energy recovery (dynamic type) by air-to-air R410A heat pump system composed of electric driven compressor (rotating or scroll type depending on unit size), evaporating and condensating reversible Cu/Al finned coils, electronic expansion valve, liquid receiver and separator, 4-way reversible valve, high and low pressure switches, biflow freon filter, liquid indicator;

- Built-in electric box to control power loads, NTC temperature sensors on both air circuits, electronic controller to control room temperature, heating/cooling mode and defrost cycles; remote control panel (up to 30 m far from the unit), already prearranged with Modbus RTU protocol for Building Management System.

Applications

Available documents