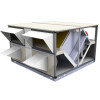

High efficiency heat recovery unit series CFR-90

These units make heavy reduction of additional heating/cooling systems for fresh air, a simplified air & water plant and very low consumption.

Description

The CFR-90 heat recovery units by SIC Srl are distinguished by a special aluminium air-to-air counterflow heat recovery exchanger, able to ensure even more than 90% efficiency.

This means a heavy reduction of additional heating/cooling systems for fresh air, a simplified air & water plant and very low consumption.

CFR-90 series units, designed for roof application or similar, match a lot of air plant configurations and use standard AC direct driven fans, which can be replaced by EC technology interchangeable fans (as an option).

The units are provided with standard F7 compact filter on each air intake, electrical board and electronic controller, able to control air temperature, free-cooling mode and fan speed. CFR-90 series is composed of six sizes, double deck version only, to cover a needing of ventilation from 300 up to 8200 m3/h.

The models of the series CFR-90 can be given with a ionization system of the air called BIOXIGEN®. This system, unique in his type, makes the air and surfsces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

This means a heavy reduction of additional heating/cooling systems for fresh air, a simplified air & water plant and very low consumption.

CFR-90 series units, designed for roof application or similar, match a lot of air plant configurations and use standard AC direct driven fans, which can be replaced by EC technology interchangeable fans (as an option).

The units are provided with standard F7 compact filter on each air intake, electrical board and electronic controller, able to control air temperature, free-cooling mode and fan speed. CFR-90 series is composed of six sizes, double deck version only, to cover a needing of ventilation from 300 up to 8200 m3/h.

The models of the series CFR-90 can be given with a ionization system of the air called BIOXIGEN®. This system, unique in his type, makes the air and surfsces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

Technical features

• Frame made from extruded Anticorodal 63 aluminium alloy bars, connected by 3-way reinforced nylon joints;

• Sandwich panels, 23 mm thickness, galvanized sheet metal inner skin and precoated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation;

• Filtering sections at both air intakes complete with F7 efficiency cell filters with polypropylene media, extractable from side removable panels;

• Full-range controlled direct driven double inlet forward curved centrifugal fans; as an option, low consumption EC technology motors;

• Air-to-air aluminium counterflow heat recovery device, efficiency over 90%;

• Electrical box with main switch and control electronics, NTC temperature sensors on fresh air, return air and exhaust air. Controlled functions: - airflow rate (by manual selection or by pressure sensor/CO2 sensor, as option) - automatic free-cooling mode - heat recovery defrosting/icing prevention by preheating (basic unit) or by airflow ratio change (unit with EC fans) - water heating/cooling (changeover) coil - additional heating system on/off signal - air filter condition (by pressure switch, as option) - clock setting;

• Remote control panel, already prearranged with Modbus RTU protocol for Building Management System.

• Sandwich panels, 23 mm thickness, galvanized sheet metal inner skin and precoated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation;

• Filtering sections at both air intakes complete with F7 efficiency cell filters with polypropylene media, extractable from side removable panels;

• Full-range controlled direct driven double inlet forward curved centrifugal fans; as an option, low consumption EC technology motors;

• Air-to-air aluminium counterflow heat recovery device, efficiency over 90%;

• Electrical box with main switch and control electronics, NTC temperature sensors on fresh air, return air and exhaust air. Controlled functions: - airflow rate (by manual selection or by pressure sensor/CO2 sensor, as option) - automatic free-cooling mode - heat recovery defrosting/icing prevention by preheating (basic unit) or by airflow ratio change (unit with EC fans) - water heating/cooling (changeover) coil - additional heating system on/off signal - air filter condition (by pressure switch, as option) - clock setting;

• Remote control panel, already prearranged with Modbus RTU protocol for Building Management System.

Applications

Available documents