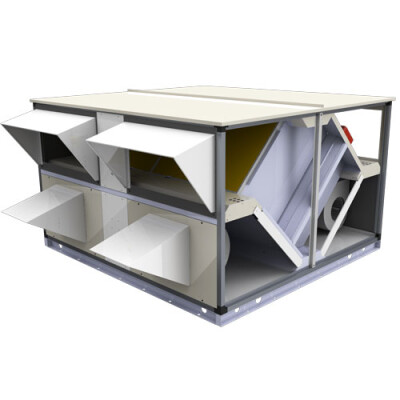

Low energy consumption fresh AHU series CFR-HEXA

These units can be an autonomous plant design solution, easy and efficient, or traditional air-conditioning sistems’ integration

Description

HEXA fresh air handling units by SIC Srl are distinguished by twin heat recovery system, along with a summer fresh air indirect adiabatic water cooler helping to reduce the installed power.

Thanks to high efficiency scroll compressors (variable flow inverter driven type as an option) and EC motor fans, the purpose of heat loads & ventilation control is always to achieve the highest system efficiency, the highest reduction of energy consumption and pollutant emissions.

Equipped with the needed additional treatment optional systems, these units may be a stand-alone plant solution or can well integrate central heating/cooling systems, both series and parallel layout.

To cover a need of fresh air from 2800 up to 15500 m3/h, HEXA series is composed of five sizes, double deck version only.

The models of HEXA series can be fitted with the BIOXIGEN® air ionization system. This system, unique in his type, makes the air and surfaces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

Thanks to high efficiency scroll compressors (variable flow inverter driven type as an option) and EC motor fans, the purpose of heat loads & ventilation control is always to achieve the highest system efficiency, the highest reduction of energy consumption and pollutant emissions.

Equipped with the needed additional treatment optional systems, these units may be a stand-alone plant solution or can well integrate central heating/cooling systems, both series and parallel layout.

To cover a need of fresh air from 2800 up to 15500 m3/h, HEXA series is composed of five sizes, double deck version only.

The models of HEXA series can be fitted with the BIOXIGEN® air ionization system. This system, unique in his type, makes the air and surfaces of the machine, of the ducts and of the bordering rooms healthy and good smelling.

Technical features

• Frame made from extruded Anticorodal 63 aluminium alloy bars, connected by 3-way reinforced nylon joints

• Sandwich panels, 48 mm thick, galvanized sheet metal inner skin and pre-coated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation

• Filtering sections at both air intakes and already fitted with pressure switch, complete with 98 mm thick. G4 efficiency cell filters, extractable from side removable panels; F9 bag filter section on supply side as an option

• EC motor direct driven backward curved plug fans; speed control electronics already fitted in the motor

• Fresh air indirect adiabatic water cooler (on summer mode), composed of flock PVC evaporating pack, upper equalized diffuser and lower water pump; re-use of water from fresh air dehumidification by summer evaporator

• First step of energy recovery (static type) by high efficiency air-to-air cross flow aluminium plated heat exchange, already equipped with motorised by-pass device for free-cooling mode

• Second step of energy recovery (dynamic type) by air-to-air R410A heat pump system composed of two electric driven scroll compressors (each on/off controlled), evaporating and condensating reversible Cu/Al finned coils, electronic expansion valves, liquid receivers, 4-way reversible valves, high and low pressure switches, biflow freon filters, liquid indicators; single variable flow inverter driven scroll compressor as an option in place of standard ones

• Built-in electric box to control power loads, NTC temperature sensors on both air circuits, electronic controller to control room temperature (supply temperature in case of variable flow compressor), free-cooling, heating/cooling mode and defrost cycles; remote control panel (up to 30 m far from the unit), already prearranged with Modbus RTU protocol for Building ManagementWR water-to-water heat pumps

• Sandwich panels, 48 mm thick, galvanized sheet metal inner skin and pre-coated (RAL 9002) sheet metal outer skin; 45 kg/m3 density foamed polyurethane as heat and sound insulation

• Filtering sections at both air intakes and already fitted with pressure switch, complete with 98 mm thick. G4 efficiency cell filters, extractable from side removable panels; F9 bag filter section on supply side as an option

• EC motor direct driven backward curved plug fans; speed control electronics already fitted in the motor

• Fresh air indirect adiabatic water cooler (on summer mode), composed of flock PVC evaporating pack, upper equalized diffuser and lower water pump; re-use of water from fresh air dehumidification by summer evaporator

• First step of energy recovery (static type) by high efficiency air-to-air cross flow aluminium plated heat exchange, already equipped with motorised by-pass device for free-cooling mode

• Second step of energy recovery (dynamic type) by air-to-air R410A heat pump system composed of two electric driven scroll compressors (each on/off controlled), evaporating and condensating reversible Cu/Al finned coils, electronic expansion valves, liquid receivers, 4-way reversible valves, high and low pressure switches, biflow freon filters, liquid indicators; single variable flow inverter driven scroll compressor as an option in place of standard ones

• Built-in electric box to control power loads, NTC temperature sensors on both air circuits, electronic controller to control room temperature (supply temperature in case of variable flow compressor), free-cooling, heating/cooling mode and defrost cycles; remote control panel (up to 30 m far from the unit), already prearranged with Modbus RTU protocol for Building ManagementWR water-to-water heat pumps

Available documents