Focus Around the world

This article is over 3 years old

Germany to convey green hydrogen in the country’s natural gas network

Researchers of the Fraunhofer Institute have developed a technology that separates green hydrogen from natural gas, conveyed together through the same network

I ricercatori del Fraunhofer Institute for Ceramic Technologies and Systems IKTS hanno sviluppato una tecnologia per ottenere la separazione dell’idrogeno verde dal gas naturale: in questo modo le due sostanze possono essere immesse insieme nella rete nazionale del gas naturale, per poi essere isolate l’una dall’altra quando arrivano alla destinazione finale.

Researchers of the Fraunhofer Institute for Ceramic Technologies and Systems IKTS have come up with a technology that can separate green hydrogen from natural gas. This would allow both substances to be introduced in the country’s natural gas network and be separated from each other when they reach destination.

These are the results of HYPOS (Hydrogen Power Storage & Solutions East Germany), a project that saw the collaboration of more than 130 partners and whose purpose was that of supplying green hydrogen – a product from renewable sources – to the entire nation by coalescing the electricity and gas networks, storage stations and hydrogen pipelines into a single smart structure.

With sustainable hydrogen, the main problem is how to move it from producer to consumer. Germany, in fact, does not have a hydrogen distribution network but it does have a 511,000 km-long gas network with 33 storage stations; now, thanks to the Fraunhofer Institute which developed the technology to separate hydrogen from gas, it will be possible to use the existing network to convey these two gases at the same time.

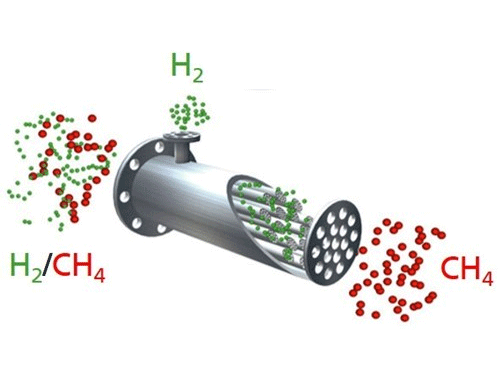

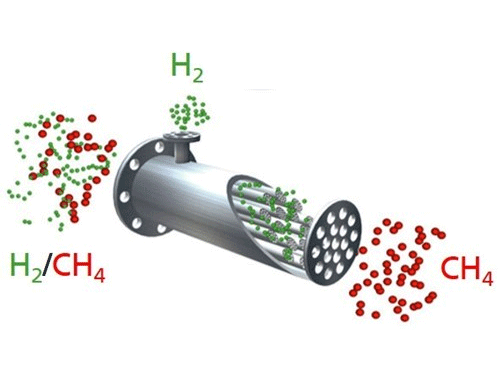

Playing a key role in the German innovation is carbon, which forms an ultra-thin layer on porous ceramic substrates where it acts as a membrane and separates the natural gas and hydrogen. Various process are used to create this membrane, including custom polymer synthesis whereby polymers are applied to the porous substrate and, when heated free of oxygen, they form a carbon layer on the surface. The carbon pores have a diameter of less than a nanometre which is why they are able to separate the two gases: the small hydrogen molecules pass through the membranes while the larger methane molecules – methane is the primary component of natural gas – are held back.

Fraunhofer IKTS worked together with several partners to create tubular carbon membranes through which the hydrogen and natural gas are pushed. This process delivers hydrogen with a purity of 80%; a second separation process is then used to filter the hydrogen further, achieving over 90% purity.

The resource obtained through the new transport and separation processes can be used in various applications and, in particular, in steel production and in energy supply to buildings.

Researchers of the Fraunhofer Institute for Ceramic Technologies and Systems IKTS have come up with a technology that can separate green hydrogen from natural gas. This would allow both substances to be introduced in the country’s natural gas network and be separated from each other when they reach destination.

These are the results of HYPOS (Hydrogen Power Storage & Solutions East Germany), a project that saw the collaboration of more than 130 partners and whose purpose was that of supplying green hydrogen – a product from renewable sources – to the entire nation by coalescing the electricity and gas networks, storage stations and hydrogen pipelines into a single smart structure.

With sustainable hydrogen, the main problem is how to move it from producer to consumer. Germany, in fact, does not have a hydrogen distribution network but it does have a 511,000 km-long gas network with 33 storage stations; now, thanks to the Fraunhofer Institute which developed the technology to separate hydrogen from gas, it will be possible to use the existing network to convey these two gases at the same time.

Playing a key role in the German innovation is carbon, which forms an ultra-thin layer on porous ceramic substrates where it acts as a membrane and separates the natural gas and hydrogen. Various process are used to create this membrane, including custom polymer synthesis whereby polymers are applied to the porous substrate and, when heated free of oxygen, they form a carbon layer on the surface. The carbon pores have a diameter of less than a nanometre which is why they are able to separate the two gases: the small hydrogen molecules pass through the membranes while the larger methane molecules – methane is the primary component of natural gas – are held back.

Fraunhofer IKTS worked together with several partners to create tubular carbon membranes through which the hydrogen and natural gas are pushed. This process delivers hydrogen with a purity of 80%; a second separation process is then used to filter the hydrogen further, achieving over 90% purity.

The resource obtained through the new transport and separation processes can be used in various applications and, in particular, in steel production and in energy supply to buildings.