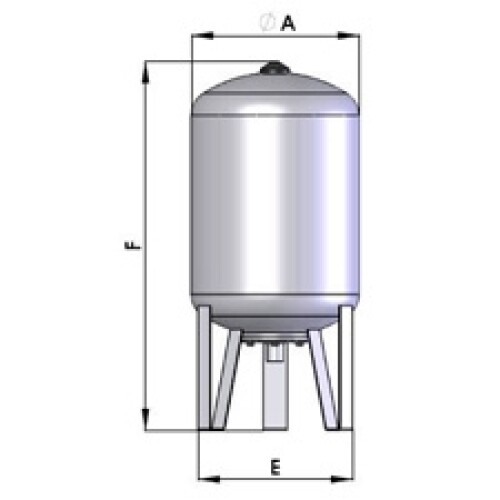

Expansion vessels

Expansion vessels: safety and stability in hydronic systems

Expansion vessels are essential components in heating, cooling, and water distribution systems. Their primary function is to compensate for fluid volume variations caused by temperature changes, preventing excessive pressure within the system that could damage the installation.

Thanks to these devices, it is possible to maintain a safe and stable operation of the hydronic system, reducing the risk of failures and extending the lifespan of the equipment

How expansion vessels work

The operating principle of an expansion vessel is relatively simple but extremely effective. When a fluid is heated, it tends to expand, increasing the pressure within the system. Without a mechanism to compensate for this expansion, the pressure could reach dangerous levels, damaging pipes, valves, and other critical components.

The expansion vessel absorbs this excess pressure. It consists of a tank divided into two sections: one filled with air or an inert gas (such as nitrogen) and the other with the system’s fluid. When the pressure rises, the fluid enters the expansion vessel, compressing the gas and thus reducing the pressure in the main system. When the fluid’s temperature and pressure decrease, the expanded gas pushes the fluid back into the system, maintaining a constant balance.

Types of expansion vessels

There are several types of expansion vessels, designed to suit specific needs and operating conditions. The main categories include:

- Open expansion vessels: These vessels are installed at the highest point of the system and are in direct contact with the atmosphere. The pressure within the system is kept constant through the vessel's opening, which allows excess water to flow freely. Although less common in modern heating systems, open expansion vessels are still used in certain applications, particularly in older systems or situations where easy maintenance is an advantage.

- Closed expansion vessels: These are the most common in modern heating and cooling systems. Unlike open vessels, they are completely sealed and use a diaphragm or membrane to separate the fluid from the gas. This design reduces maintenance requirements and prevents internal corrosion since the fluid is not exposed to air.

- Membrane expansion vessels: In these vessels, a flexible membrane divides the tank into two compartments: one for the fluid and the other for air or an inert gas. This type of expansion vessel provides better pressure management and greater durability compared to fixed-chamber models, as it can absorb larger volume variations without excessively stressing the system.

- Expansion vessels for solar systems: Specifically designed for solar thermal systems, these vessels are built to withstand extremely high temperatures and intense pressure cycles. They use heat-resistant and UV-resistant materials, ensuring long-term durability even under severe operating conditions.