How to evaluate differences in residential heat recovery ventilation units

How to choose a recovery ventilation system, a short guide

Heat recovery ventilation systems for residential use significantly differ from one to another, with respect to the type of construction, functionality and performance.

This technical file shall present a comprehensive analysis regarding this type of ventilation system, also taking into account most recent technological and regulatory developments, including information about how to distinguish different machines and evaluate them, according to their structure and components, as well as different functions and performances.

Structure |

|||

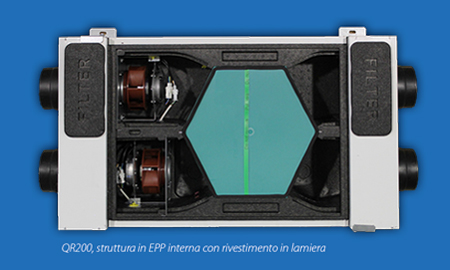

The structure of the unit is critical and determines the amount of thermal and acoustic insulation achieved. Thermal insulation is vital to the efficiency of the unit and is required to prevent thermal bridges: these cause condensation to build on the surface of the casing and can damage both the house and the unit itself. The unit structure can be made from metal sheet with insulating mat; double sheet panelling with insulating material on the inside (normally EPS, polystyrene, fibreglass or polyurethane foam); self-supporting EPP (expanded polypropylene); or from coated sheet EPP.

The sheet structure is inexpensive and easily made, but it has very limited thermal and acoustic insulation. This system also suffers from unavoidable thermal bridges and so is not used in any high quality products. |

The double panelled structure guarantees good thermal and acoustic insulation. Furthermore, it is solid, it does not need investment, and the inside is easily cleaned. However, localised thermal bridges are unavoidable, especially where the external and internal sheets are in contact with each other. Over time, the collection and discharge of condensation causes issues, because condensation builds on the metal walls and the sheet interstices, dripping outside the unit. This moisture compromises the insulation between the panels and can lead to the growth of mould. Furthermore, because the insulating materials are not visible inside the panels if, during the production process, some filling problems occur, it will compromise the quality and create thermal bridges. Being air-tight is always critical, in particular referring to the seal life. The EPP (expanded polypropylene) self-supporting structure guarantees good thermal and acoustic insulation, without external thermal bridges (unless the connections between the fittings of the distribution network's piping are poorly made). The EPP structure with coated sheet guarantees the best thermal and acoustic insulation as it has the advantages of both the coated sheet and EPP types. |

||

For more details and information on the types of construction, performances, fans and heat recovery ventilation systems for residential use, you can download the pdf file for free. |

|

||