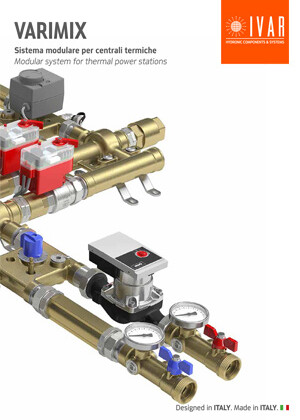

Control Unit Varimix - Ivar

The diversification of uses often crashes against the need for concentrating the hydraulic system components and controls in a single dedicated area: in this respect, the mechanical room is at the same time the heart and the brain of the building, a room to design in the light of the needs and of the user preferences over twelve months.

Description

IVAR substations allow to arrange the mechanical room according to a new concept of space and functionality. These groups give the opportunity to manage multiple thermal zones with different characteristics as truly independent zones in a neat, rational space, thanks to their modular structure and outstanding installation flexibility.

VARIMIX substation is suitable to large residential thermal power plants. VARIMIX allows to pump heating fluid to different heating zones at different temperatures by independent distribution/booster kits, available with or without mixing valve and equipped with electronic circulator pumps, besides featuring all the necessary monitoring, safety and shut-off accessories. The primary side and the distribution side are hydraulically separated by a pressure equaliser complete with filter and automatic air vent valve.

Mixing valve in low temperature kit is a rotor three way valve, proposed in two versions having different flow coefficients. When in presence of a traditional high temperature heat generator, it is often necessary to increase the return temperature to avoid the onset of corrosion phenomena: in such cases it is possible to choose the kit versions equipped with four-way mixing valve, also available in two variants with different flow coefficients. Regardless the type, mixing valve is actuated by a rotary servomotor with 90°-stroke, connected to a climatic controller.

Each component is individually insulated, and the distribution kits with the relative modular manifolds can be installed with upwards or downwards flow lines. VARIMIX can also be used in cooling applications, by uncoupling the operation of heating-only kits from that of heating/cooling kits through the installation of two zone valves between the modular manifolds of the two sections.

Materials

Cast brass parts: CB753S

Other brass components: CW617N

Gaskets and o-rings: peroxide EPDM

Insulation shell: polystyrene or expanded polypropylene

VARIMIX substation is suitable to large residential thermal power plants. VARIMIX allows to pump heating fluid to different heating zones at different temperatures by independent distribution/booster kits, available with or without mixing valve and equipped with electronic circulator pumps, besides featuring all the necessary monitoring, safety and shut-off accessories. The primary side and the distribution side are hydraulically separated by a pressure equaliser complete with filter and automatic air vent valve.

Mixing valve in low temperature kit is a rotor three way valve, proposed in two versions having different flow coefficients. When in presence of a traditional high temperature heat generator, it is often necessary to increase the return temperature to avoid the onset of corrosion phenomena: in such cases it is possible to choose the kit versions equipped with four-way mixing valve, also available in two variants with different flow coefficients. Regardless the type, mixing valve is actuated by a rotary servomotor with 90°-stroke, connected to a climatic controller.

Each component is individually insulated, and the distribution kits with the relative modular manifolds can be installed with upwards or downwards flow lines. VARIMIX can also be used in cooling applications, by uncoupling the operation of heating-only kits from that of heating/cooling kits through the installation of two zone valves between the modular manifolds of the two sections.

Materials

Cast brass parts: CB753S

Other brass components: CW617N

Gaskets and o-rings: peroxide EPDM

Insulation shell: polystyrene or expanded polypropylene

Technical features

Max working temperature (except pumps): 120 °C

Max working pressure: 10 bar

Max flow rate at primary inlet: 4500 l/h

Modular manifolds and pressure equaliser:

- Primary connections, pressure equaliser connections: G 1 1/4'' F

- Centre distance between primary side connections: 100 mm

- Secondary connections: G 1 1/4'' F (swivelling)

- Centre distance between secondary connections: 100 mm

Distribution kits:

- Connections to manifold: G 1 1/4'' M

- Centre distance between connections to distribution system: 100 mm

Max working pressure: 10 bar

Max flow rate at primary inlet: 4500 l/h

Modular manifolds and pressure equaliser:

- Primary connections, pressure equaliser connections: G 1 1/4'' F

- Centre distance between primary side connections: 100 mm

- Secondary connections: G 1 1/4'' F (swivelling)

- Centre distance between secondary connections: 100 mm

Distribution kits:

- Connections to manifold: G 1 1/4'' M

- Centre distance between connections to distribution system: 100 mm

Applications

Available documents