Pipes

Piping: key components for system efficiency

Piping is a fundamental element in numerous industrial sectors, including HVAC (Heating, Ventilation, and Air Conditioning), hydraulic, electrical, and mechanical systems. These components are essential for the safe and efficient transport of fluids and gases, ensuring the proper functioning of installations.

In this article, we will explore the characteristics of piping, its advantages, how it works, and key considerations for its selection and installation.

Characteristics of piping

Piping can be made from various materials, including stainless steel, copper, PVC, polyethylene (PE), polypropylene (PP), and composite materials. The choice of material depends on the application, operating conditions, and requirements for strength and durability.

It comes in different sizes, with varying diameters and thicknesses to suit specific project needs. The piping dimensions influence the flow rate and pressure of the transported fluid.

Piping can be joined through welding, mechanical joints, threaded fittings, flanges, or compression joints. The choice of connection method depends on the type of material and the application.

Corrosion resistance is a critical feature for piping used in harsh environments or for transporting corrosive fluids. Materials such as stainless steel and PVC offer excellent anti-corrosion properties.

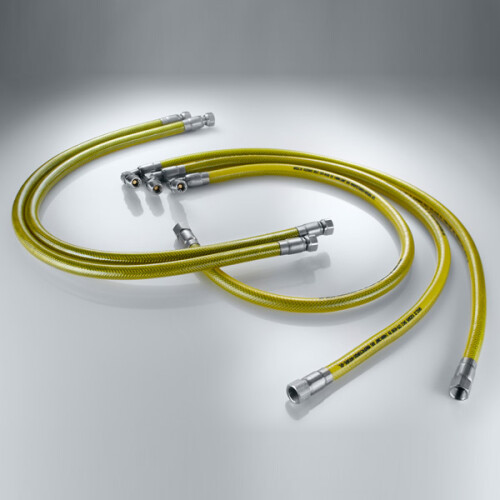

The flexibility or rigidity of piping varies based on material and construction. Flexible piping is ideal for applications requiring adaptability and easy installation, while rigid piping provides greater stability and strength.

What are the functions of piping?

Piping is used to transport fluids and gases from one point to another within a system. The fluid or gas is pushed through the piping using pumps, compressors, or the system’s natural pressure.

It forms a distribution network that connects various system components, such as tanks, heat exchangers, valves, and process equipment.

Flow control devices, such as valves, are integrated into the piping system to regulate pressure, flow rate, and the direction of the transported fluid or gas.

In certain applications, piping can be thermally insulated to reduce heat loss or cooling loss and acoustically insulated to minimize noise.

Piping innovations

The use of advanced composite materials, such as reinforced fiberglass and high-performance polymers, is enhancing the strength and durability of piping.

New anti-corrosion and antimicrobial coating technologies are extending the lifespan of piping and improving the safety of fluid transport.

The integration of sensors and remote monitoring systems allows real-time tracking of piping operating conditions, quickly detecting leaks and anomalies.

Next-generation flexible piping offers greater adaptability and easier installation, reducing labor costs and improving performance.