Focus Companies

Apros S.r.l.

• 04.11.2015

This article is over 3 years old

Apros metal chimneys for the evacuation of the combustion fumes: safety and energy saving

Apros: solutions for stoves, wood and pellet boilers and for natural gas boilers. The chimney systems in stainless steel, perfect even for the respect of the environment.

The technological development and the increasing research in the field of heat generators have brought to a progressive improvement of the ducts for the evacuation of fumes from combustion.

Apros, thanks to a continuous research in the field of metal chimneys, can always propose some new solutions such as Unix, and new materials such as aluminized steel; everything to achieve a greater energy saving; to limit the environmental pollution and to increase safety avoiding fires or dispersion of carbon monoxide inside the house.

It is essential for Apros to follow all the legislative framework of the sector. Products Made in Apros are all CE marked as required by standard UNI-EN 1443 and from the Ministerial Decree 37/08, which define all the features of the duct and performance, obliging since 2005 the installation of a certified system for the evacuation of fumes.

Dynamic Two, stainless steel chimney system in double wall for outdoor, follows for example the regulation UNI EN 1856-1 and 2.

Apros, which has a wide range of products, is able to propose the most suitable solutions for each installation:

The rule UNI 10683 concerns stoves and wood or pellet boilers, it deals with systems which are fed with wood or other biofuels, and defines the requirements for verification, installation, monitoring and maintenance of plants destined to the room heating and / or the production of sanitary hot water and / or the cooking of food, with both natural draught appliances (ex. wood stove) smoke side, and forced draught appliances (ex. pellets), with rated thermal output <= 35 kW-powered by solid biofuels.

The products of combustion must be discharged to the roof, and the chimney should always work in depression. The junctions, finally, must be secured with metal clamps for tighten pipes.

It is essential to keep in mind the height of the terminal outlet, which must not be located in reflux area on the roof, as it could cause the "cap effect", compromising the draught and the security of the system.

Thanks to its own calculation software of the latest generation, Apros is able to provide the dimensional calculation.

Once the system installation is completed, the authorized installer must carry out the necessary tightness and draught tests of the system with the appropriate instrumentation, and fill in the "Chimney plate" provided by the manufacturer. The installer has also to fill in the declaration of conformity and the system installation book.

The frequency of maintenance procedures should not exceed 4 t of fuel and 2 years for the cleaning. Apros recommends checking and cleaning the pipes at least once a year.

.jpg) The UNI EN 7129-3 is the reference standard for the design and the installation of systems for the evacuation of combustion products which are at the service of household plants and similar, for the use of combustible gases.

The UNI EN 7129-3 is the reference standard for the design and the installation of systems for the evacuation of combustion products which are at the service of household plants and similar, for the use of combustible gases.

Even with the gas systems for domestic use, the discharge of the products for combustion must take place on the roof.

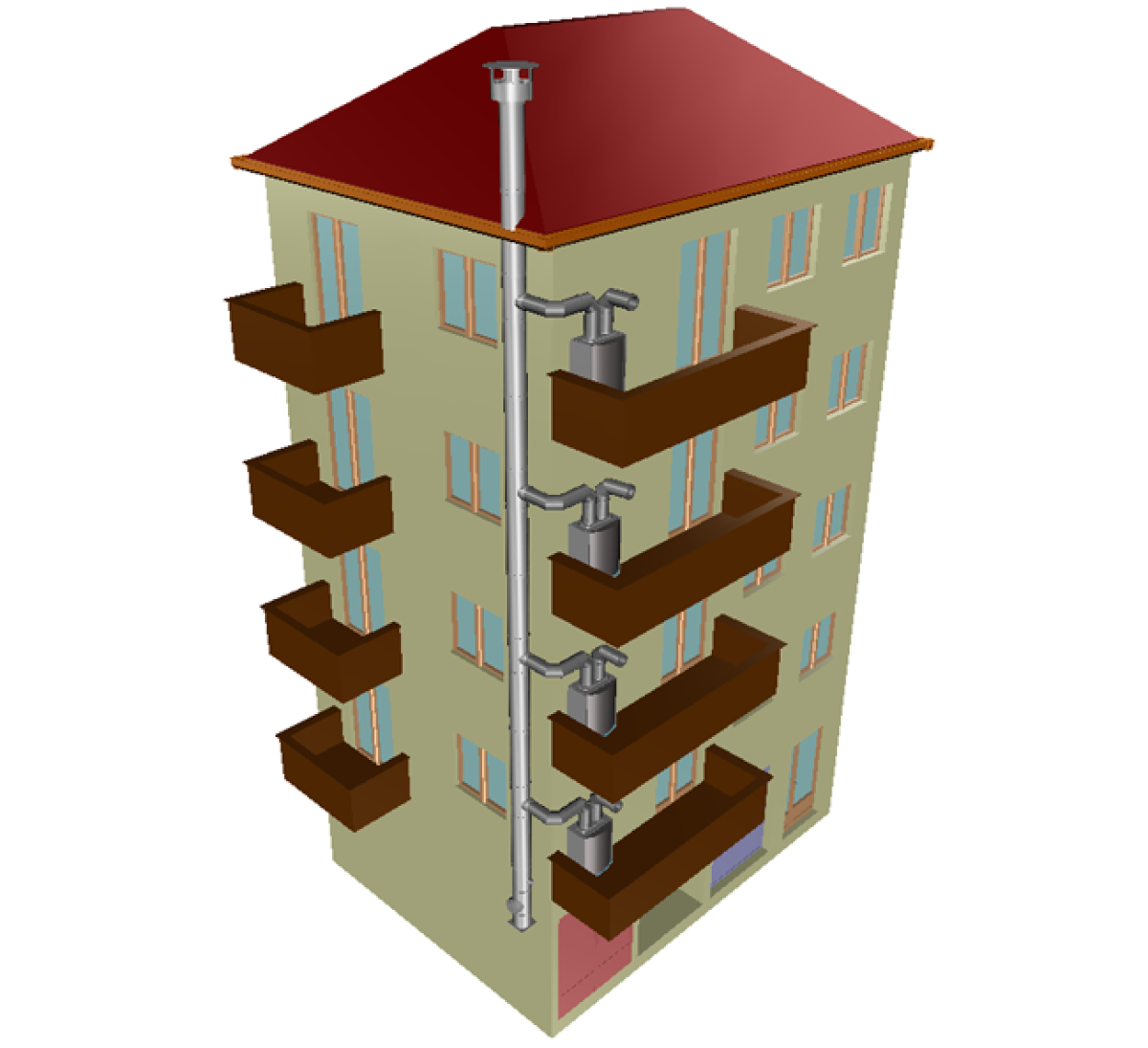

Apros has dimensioned a system in collective with four users (see the diagram below), with boilers of type C fueled by methane gas, taking into account the minimum depression of the system at 17 Pa (height Hc) and assuring, even in the last user, a depression of at least 3 Pa (height Tt).

It is necessary to respect even the share of reflux (the wind), to avoid the return of the fumes (height Ht).

The system must also assure the discharge of the condensation to the base with special duct, and have an inspection chamber and collected unburned.

Apros, thanks to a continuous research in the field of metal chimneys, can always propose some new solutions such as Unix, and new materials such as aluminized steel; everything to achieve a greater energy saving; to limit the environmental pollution and to increase safety avoiding fires or dispersion of carbon monoxide inside the house.

It is essential for Apros to follow all the legislative framework of the sector. Products Made in Apros are all CE marked as required by standard UNI-EN 1443 and from the Ministerial Decree 37/08, which define all the features of the duct and performance, obliging since 2005 the installation of a certified system for the evacuation of fumes.

Dynamic Two, stainless steel chimney system in double wall for outdoor, follows for example the regulation UNI EN 1856-1 and 2.

Apros, which has a wide range of products, is able to propose the most suitable solutions for each installation:

- Wood line 2 mm for the connecting flue pipes;

- Pellet line 1,2 mm for the connecting flue pipes;

- Enameled wood line for the connecting flue pipes;

- Enameled pellet line for the connecting flue pipes;

- Dynamic One line thickness 0,5 mm (single wall stainless steel 316L) connecting flue pipes / chimney systems;

- Dynamic One black thickness 0,5 mm for the connecting flue pipes;

- Dynamic Two thickness 0,5 mm (double wall stainless steel 316L with 25 mm of insulation material);

- Metal chimneys with outer wall to be chosen among Copper, Black paint Steel or oxidized Copper.

Metal Chimneys for the installation of stoves and wood or pellet boilers

The rule UNI 10683 concerns stoves and wood or pellet boilers, it deals with systems which are fed with wood or other biofuels, and defines the requirements for verification, installation, monitoring and maintenance of plants destined to the room heating and / or the production of sanitary hot water and / or the cooking of food, with both natural draught appliances (ex. wood stove) smoke side, and forced draught appliances (ex. pellets), with rated thermal output <= 35 kW-powered by solid biofuels.

The products of combustion must be discharged to the roof, and the chimney should always work in depression. The junctions, finally, must be secured with metal clamps for tighten pipes.

It is essential to keep in mind the height of the terminal outlet, which must not be located in reflux area on the roof, as it could cause the "cap effect", compromising the draught and the security of the system.

Thanks to its own calculation software of the latest generation, Apros is able to provide the dimensional calculation.

Once the system installation is completed, the authorized installer must carry out the necessary tightness and draught tests of the system with the appropriate instrumentation, and fill in the "Chimney plate" provided by the manufacturer. The installer has also to fill in the declaration of conformity and the system installation book.

The frequency of maintenance procedures should not exceed 4 t of fuel and 2 years for the cleaning. Apros recommends checking and cleaning the pipes at least once a year.

Metal Chimneys for the installation of natural gas boilers

.jpg) The UNI EN 7129-3 is the reference standard for the design and the installation of systems for the evacuation of combustion products which are at the service of household plants and similar, for the use of combustible gases.

The UNI EN 7129-3 is the reference standard for the design and the installation of systems for the evacuation of combustion products which are at the service of household plants and similar, for the use of combustible gases.

Even with the gas systems for domestic use, the discharge of the products for combustion must take place on the roof.

Apros has dimensioned a system in collective with four users (see the diagram below), with boilers of type C fueled by methane gas, taking into account the minimum depression of the system at 17 Pa (height Hc) and assuring, even in the last user, a depression of at least 3 Pa (height Tt).

It is necessary to respect even the share of reflux (the wind), to avoid the return of the fumes (height Ht).

The system must also assure the discharge of the condensation to the base with special duct, and have an inspection chamber and collected unburned.

Available documents